by Galvatech | Aug 21, 2023 | Frequently Asked Questions

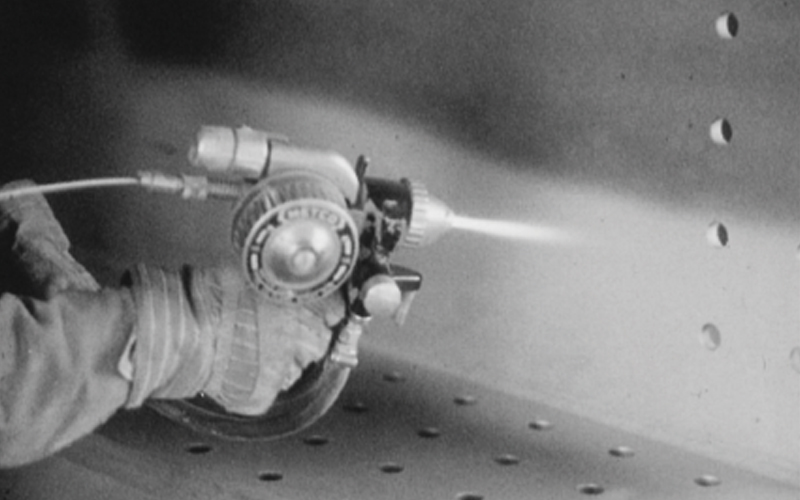

In order to conduct such a comparison it is necessary to first understand the two processes. Hot Dip Galvanizing Hot dip galvanizing is a metallurgical process that results when “perfectly” cleaned steel is immersed into molten zinc at 450C. In other words the...

by Galvatech | Aug 21, 2023 | Frequently Asked Questions

Causes When steel components are heated to the hot dip galvanizing temperature of approximately 450C, internal stresses can be released resulting in distortion. At this temperature, the limit of elasticity and the value of Young’s Modulus of the steel are reduced to...

by Galvatech | Aug 21, 2023 | Frequently Asked Questions

Used by the HDGASA to determine Service Life of Hot Dip Galvanized Steel Exposedto Various Atmospheric Environments Reference Source: ISO 9223:2012Summary of ISO 9223 Specification The ISO 9223 specification considers key factors in determining the atmospheric...

by Galvatech | Aug 21, 2023 | Frequently Asked Questions

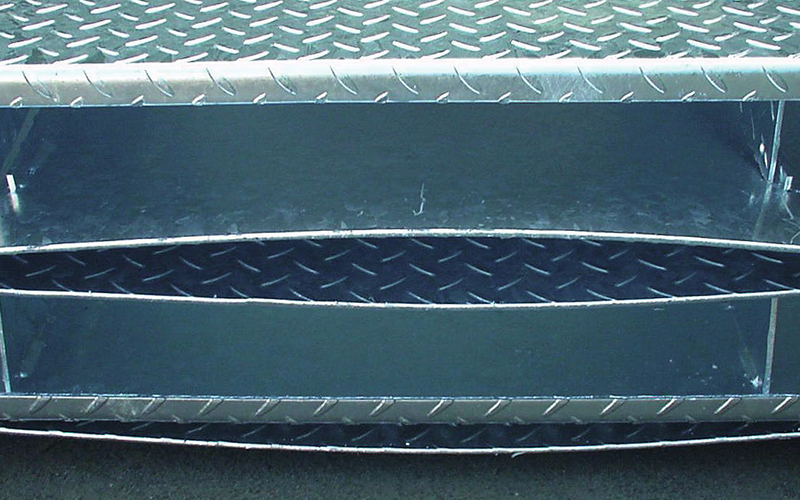

The quality and surface finish of hot dip galvanized carbon steels are directly related to the chemistry of the components being processed. Fundamentally, two elements, being Silicon (Si) and Phosphorous (P) within carbon steel, influence the surface finish in terms...

by Galvatech | Aug 17, 2023 | Frequently Asked Questions

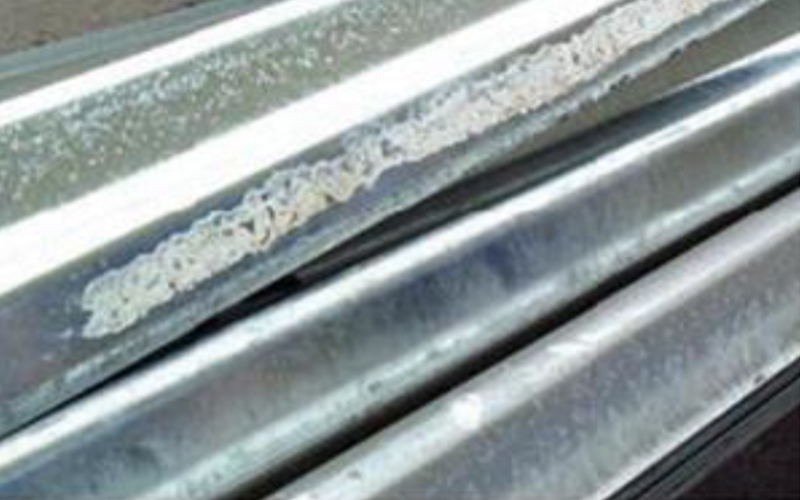

The finish and appearance of a hot dip galvanized coating is dynamic, a ‘living’ surface that visibly changes until the hot dip galvanized surface attains a stable zinc patina or zinc carbonate film which is a dense insoluble film dull-grey in colour. Wet storage...