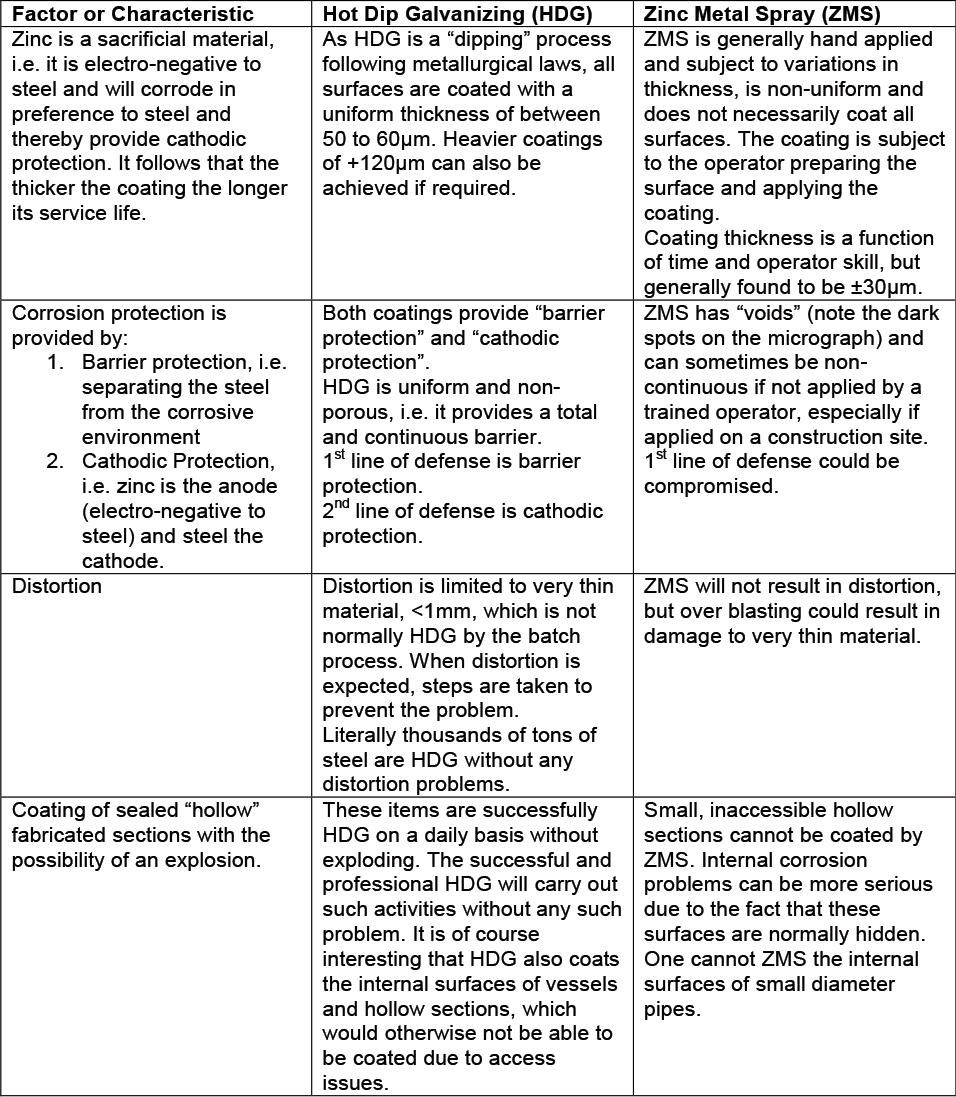

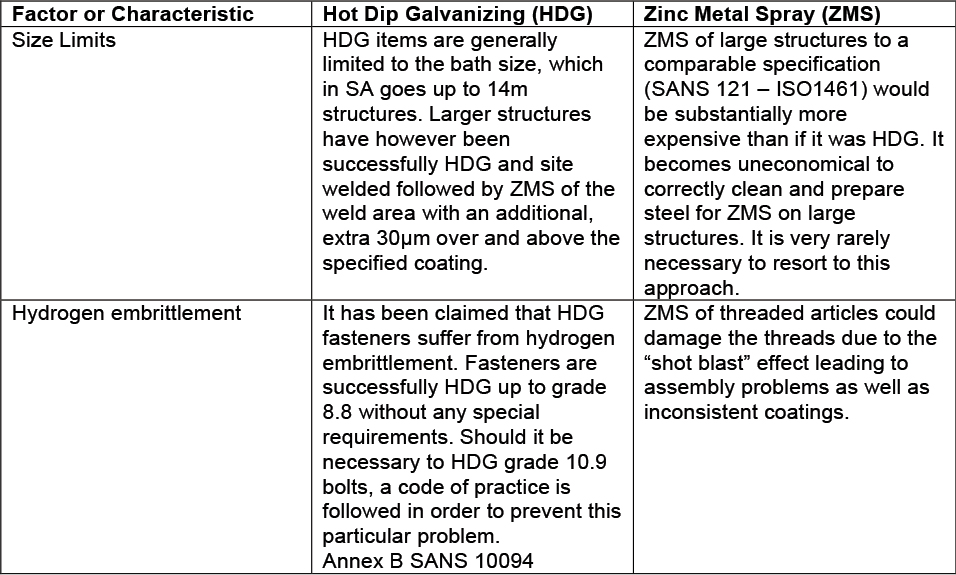

In order to conduct such a comparison it is necessary to first understand the two processes.

Hot Dip Galvanizing

Hot dip galvanizing is a metallurgical process that results when “perfectly” cleaned steel is immersed into molten zinc at 450C. In other words the coating is achieved by way of a chemical reaction between the molten zinc and the steel, forming a series of zinc iron alloys that provide a “chemical bond” between the steel and the protective coating. Adhesion is achieved as part of the process and is not dependent on human intervention.

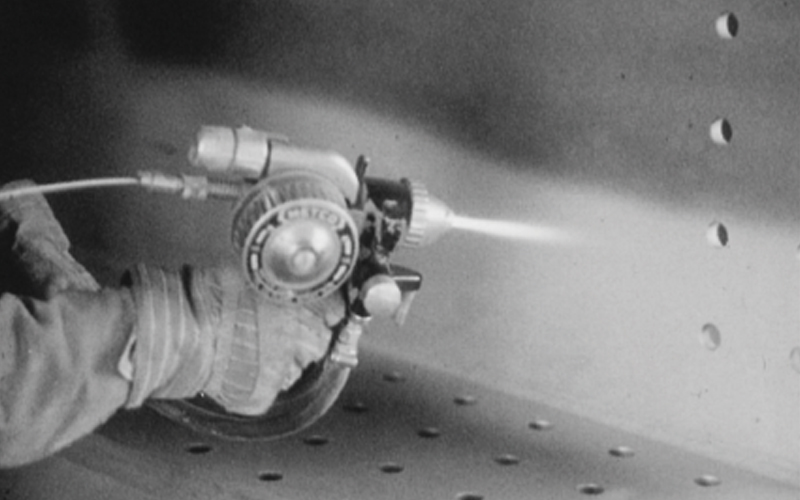

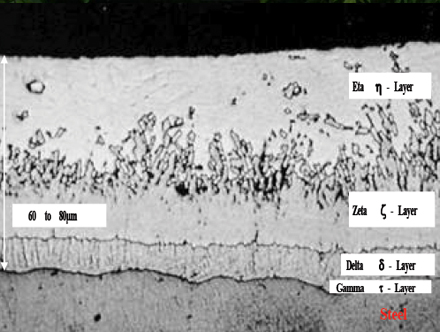

Figure 1: Typical hot dip galvanized coating on Aluminium “Killed Steel” Micrograph x 200 magnification.

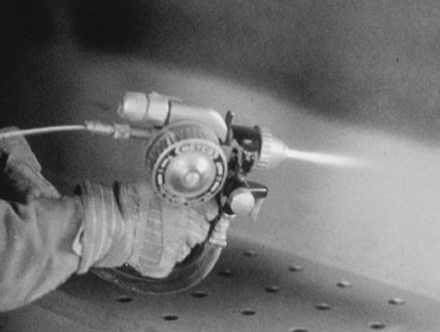

Figure 2: Hot Zinc Metal Spray Gun

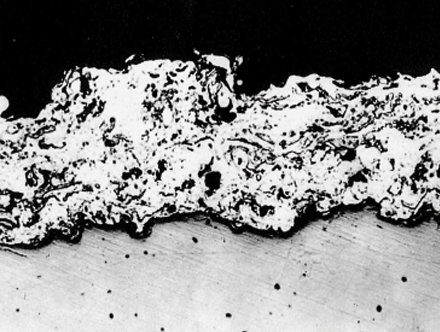

Figure 3: Typical Hot Zinc Metal Sprayed Coating.

Micrograph x 200 magnification

Zinc Metal Spray

This form of coating is achieved by passing a zinc wire through an oxygen/acetylene fired gun that melts the zinc (750C) forming minute molecules of molten zinc that are then sprayed onto the steel surface. By the very nature of the process, adhesion of the zinc to the steel is a mechanical bond, as illustrated in the micrograph of this form of coating. There is no metallurgical (chemical) bonding of the coating to the steel surface.

Having briefly illustrated the two processes and their respective micrographs, we can draw some comparisons based on the coating itself.

Comparison of Hot Dip Galvanizing & Zinc Metal Spray

In general, hot dip galvanizing is the most practical and economical corrosion protection coating available for carbon steels. Corrosion is a function of the environment, coating thickness, integrity and adhesion characteristics.

All coatings, irrespective of the type, require proper and adequate cleaning and preparation prior to the application of the barrier protection. The majority of coatings require strict supervision to ensure compliance with this requirement.

Hot dip galvanizing is called “an honest coating” in that if the steel is not correctly and adequately cleaned prior to coating, it will not galvanize! Inspection is therefore easier and limited to the end product. Likewise site inspection is also made easier and practical.

Should you require additional detail, we would be most willing to discuss the subject further. We can also provide additional information on duplex coatings (hot dip galvanizing plus a top paint coating), which you may find of interest.