The quality and surface finish of hot dip galvanized carbon steels are directly related to the chemistry of the components being processed. Fundamentally, two elements, being Silicon (Si) and Phosphorous (P) within carbon steel, influence the surface finish in terms of uniformity, colour (shiny or matt dull grey) and relative smoothness.

Carbon steels fall into two broad categories, viz,

- Aluminum killed steels, < 0.03% Si, or

- Silicon killed steels, > 0.03% Si

The term “killed steels” relates to degassing and de-oxidizing of carbon steels during their manufacturing process..

Zinc coating thickness and appearance, produced by hot dip galvanizing; at normal molten zinc temperatures of between 445 to 455°C is a function of Si% and in certain circumstances, but less frequently, by P% content within the carbon steel.

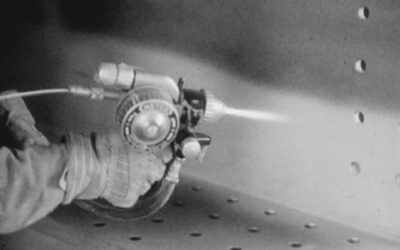

Micrographs of Hot Dip Galvanized Coatings (magnification of 150 to 200x)

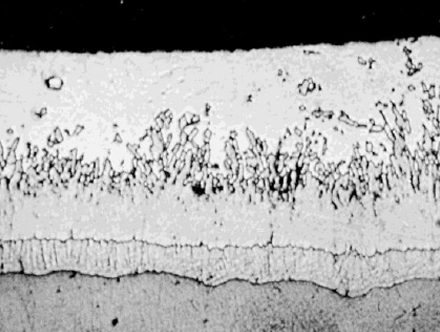

Typical micrograph of a hot dip galvanized coating using “aluminium killed” carbon steel (Silicon < 0.03% and zinc temperature 450°C)

Zinc coating thicknesses range between 50μm to 65μm

Coating surface finishes are usually a bright silvery shine, which in time (3 to 4 months) will become a dull matt grey uniform finish of ZnCO3, refer to Information sheet No. 11

“How does zinc protect?”

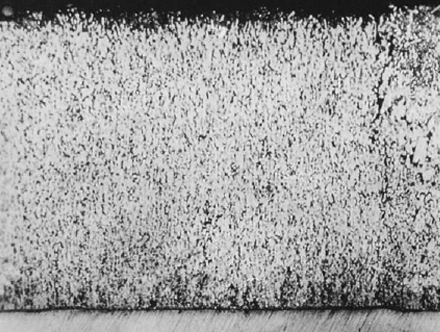

Cross-section through zinc coating on siliconkilled steel with 0.06% Si

Zinc coating thicknesses range between 150μm to 300μm and illustrated in the photograph

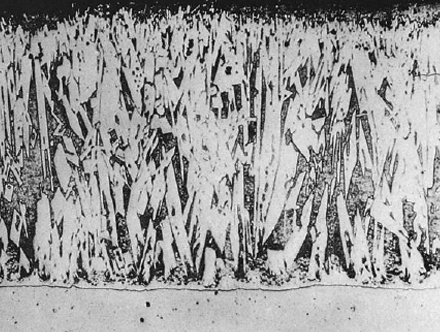

Coating structure of hot dip galvanized coating produced using “silicon killed” steel within the silicon range of 0.15% to 0.25% and a zinc temperature 450°C

Coating thicknesses range between 120μm to 200μm, and illustrated in the photograph